Vertical Raw Mill Pdf - Felona Heavy Machinery

The OK Mill was originally designed for cement grinding In 2017 we released the OK vertical roller mill for raw materials grinding The OK Mill’s modular design comes with unique flexibility showcasing parts commonality where spare parts can be shared between vertical roller mills . Learn More Hydraulic system vertical roller mill operation

loesche Vertical Mill LM 56.3.wmv - YouTube

16.11.2011 · Process in vertical raw mill

Raw Mill Loeshe Operation Flow Digram Vertical …

Hydraulic Operation In Vertical Raw Mill raw mill loeshe operation flow digram Hot 13 Jan 2014 Hydraulic machineryHydraulic equipmentshydraulic Hydraulic Operation In Vertical Raw Mill Read more vertical raw mill and cement mill operation operation of vertical raw mill cement industry 2008 to develop a larger size LGM series vertical mill slag ...

vertical raw mill operation - nausnice-eshop.cz

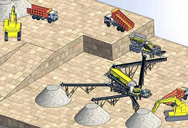

cement plant vertical raw mill maintain stable operation LM Vertical Mill integrates crushing, drying, grinding, classifying and conveying together, 11 are involved in full cement operation from raw materials. The production at the remainder of the facilities involves grinding and readymix of.

operation of vertical cement grinding mills - …

Verticalrollermills(VRM) have found applications mostly incement grinding operationswhere they were used in raw meal and finishgrindingstages and in power plants for coalgrinding. Themillcombines crushing,grinding, classification and if necessary dryingoperationsin one unit and enables to decrease number of equipment ingrinding...

operation of vertical raw mill cement industry

Vertical Cement Mill In Operation operation of vertical raw mill,islamabad cement plants machinery parts. For almost 30 years, G-Quarry has being specializing in all facets of grinding mill design and . Verticalget price. vertical coal mill operation in cement industry. Coal Mills In Cement Industry. What Is Coal Mill Of A Cement Industry Wiersmaenzoonnl. Atox coal mill operation in cement ...

kind of vibration vertical raw mill operation

Large vertical roller mill is mostly used in raw meal preparation system. In the process of process production the vibration of vertical mill has a great influence on the whole process production operation equipment maintenance and use equipment spare parts …

Milling Machine: Definition, Parts, Types, …

Straddle milling Operation: It is the operation on producing the flat vertical surface on both sides of the workpiece by using two side milling cutter mounted on the same arbor. The distance between the two cutters is adjusted by using a spacing collar. This is commonly used to produce a hexagonal or square surface. Grooves milling Operation:

Milling Machine: Parts, Types, Operations, Milling …

21.04.2018 · The end milling is the operation of producing a flat surface which may be vertical, horizontal or at an angle in reference to the table surface. The cutter used is an end mill. The end milling cutters are also used for the production of slots, grooves or keyways. A vertical milling machine is more suitable for end milling operation. 10. stone Milling

Milling (machining) - Wikipedia

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a work piece. This may be done varying direction on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations.

MVS - MINI VERTICAL SYSTEM

The users will appreciate its lightness, high mobility, economical operation, precise cutting and high quality of the surface of the sawn wood. The basic model includes 3 pieces of 2 meter modules (6 meter in total) of the travelling track with clamps, movable frame with sawing unit and power feed. TECHNICAL PARAMETERS. FEATURES OF PORTABLE SAWMILL MVS. RELIABILITY. Its already 15 years we ...

Vertical Raw Mill And Cement Mill Operation …

Vertical Raw Mill And Cement Mill Operation Crusher. Cement mill is mainly used in grinding raw materials and end products in the cement plant it is also suitable for various ores and other materials metallurgy mine stone and construction besides it has two forms of milling one is an open form and the other is. Leave Us Message Email [email protected] Online Consulting. Get Latest Price Our ...

Mill (grinding) - Wikipedia

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes.There are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (e.g., via a hand crank), working animal (e.g., horse mill), wind or water ().

(PDF) SIZE REDUCTION BY CRUSHING METHODS

All operations in size reduction, both crush ing and grinding are of course determ ined by the feed characteristics of the minerals (rock/ore ) moving into the circuit. The key parameters we need ...

vertical sawmill youtube

An accessible boardwalk and a bench provide for easy access and viewing NPS Photo The exact date of construction and first operation of the vertical sawmill near todays Owens Creek Campground is unknown, but it is shown on an 1857 map with the same area indicated as deeded back to 1808, mentioning rights to water ways

CENTRAL MACHINERY 44991 ASSEMBLY AND …

Refer to the ruler on the Vertical Support to determine drilling or milling depth. Caution: Keep hands and fingers clear of the working table and workpiece while the machine is in operation. SKU 44991 Page 7 (68) Page 8: Maintenance BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR ...

Saw Mill Machines Manufacturer,Bandsaw Cutting …

We manufacture a wide range of Cutting stone and Machines such as Band stone Cutting Machine, stone Cutting Machine and stone Mill Machine. All our creations are know for features like excellent performance, low maintenance cost, user-friendly functions, modern design and power efficiency. The range we serve is manufactured and developed using only the quality raw material, to provide …

Home - Sawmill Bandsaw China Best Supplier

2-Train the customer’s technician,And provide operation video and matters needing attention. 3-Arrange customs declaration, sea shipping, insurance, etc. After-sales service. 1-Our machines’ warranty period is 12 month, We will provided spare parts for free within 12 month,But will need customer bear the delivery cost. We charge cost price and delivery cost if the warranty period past. 2 ...