typical diameter of ball measurements of mill

typical diameter of ball measurements of mill. Ball mill Wikipedia. A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell.

typical diameter of ball sizes of mill

Ball Mills - Mineral Processing & Metallurgy. Working Principle & Operation. The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the size of a mill, for example: a 5′ x 5′ Ball Mill has a working diameter of 5′ inside the liners and has 20 per cent more capacity than all other ball ...

typical diameter of ball sizes of mill - liming …

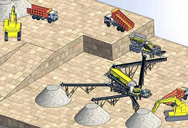

Ball Mills - Mine Engineer.Com provides mining, gold, copper, coal ... Photo of a 10 Ft diameter by 32 Ft long ball mill in a Cement Plant. ... Image of cut away ball mill, showing material flow through typical ball mill.

typical ball size of ball mill - baasrodeva.be

typical ball size mill « mining equipment Ball millWikipedia the free encyclopedia A ball mill works on the principle of impactGet Price. ... The optimal ball diameter in a mill. grinding quartz and copper ore in a laboratory ball mill there has been defined The ball size in a mill has a significantGet Price.

Typical Size Of Ball Mill - Ball Mill

End Mill Sizeschart Of Inch Metric And Micro Diameters. End mill size chart pdf the above link provides a printable and downloadable chart of the table below this table shows end mill diameter sizes for inch metric and micro milling bits from 0005 to 1 all of these sizes can be searched by clicking the end mills tab at the top of the page some inch sizes below are linked below to make it

typical ball size of ball mill - …

In connection with this , based the belief that a ball diameter of D 2 100 mm is the preferred size for ore of a . mensurable with the duration of a normal experiment. Get Price; The Effect of Ball Size Diameter on Milling Performance | OMICS . A laboratory size ball mill was used with ball media of sizes 10 m.

Ball Mill - an overview | ScienceDirect Topics

Ball mills give a controlled final grind and produce flotation feed of a uniform size. Ball mills tumble iron or steel balls with the ore. The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.-% ore and 25% steel.

Optimum choice of the make-up ball sizes for …

01-09-2013 · A grinding circuit simulation combined with ball weal law was used to determine the optimum composition of the make-up ball sizes in tumbling ball mills. It was found that the optimum composition depends on various factors, including the feed size, the product size, the mill diameter and the breakage parameters.

End Mill Sizes-Chart Of Inch Metric And Micro …

52 rijen · End Mill Size Chart (pdf) The above link provides a printable and downloadable chart of the …

EFFECT OF BALL SIZE DISTRIBUTION ON MILLING PARAMETERS

2.1 Breakage mechanisms in a ball mill 22 2.2 First order reaction model applied to milling 24 2.3 Grinding rate versus particle size for a given ball diameter 25 2.4 Cumulative breakage function versus relative size 28 2.5 Predicted variation of S i values with ball diameter for dry grinding of quartz 31

How to Size a Ball Mill -Design Calculator & Formula

15-05-2015 · A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill volume (inside liners). B) Overflow Discharge Mills operating at low ball fillings – slurry may accumulate on top of the ball charge; causing, the Total Charge Filling Level to ...

Ball mill - Wikipedia

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering.It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical

Typical Ball End Mill Sizes - relaxrecreatiemakelaar.nl

Typical Ball End Mill Sizes. FOB Reference Price: Get Latest Price. 2017-8-13Im in a similar predicament but my issue is End Mill types were currently machining components that are made out of EN40b alloy steel struggling to get End Mills to last. Components not very big so End Mills sizes are 14 and 516 open end milling and slot milling.

typical ball size mill,how to make rolling mill

Ball Mills - Mineral Processing Metallurgy. Working Principle Operation. The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the size of a mill, for example: a 5′ x 5′ Ball Mill has a working diameter of 5′ inside the liners and has 20 per cent more capacity than all other ball ...