Polymetallic Flotation Equipment - Complete Ore Process Plant

This ore processing plant is for the flotation of 2 base metals (Cu/Pb/Zn/Co/Ni/etc.) which may or may not contain precious metals. These ore deposits are called polymetallic by geologists and metallurgists. This system allows you to recovery by way of differential or sequential flotatio, the sulphide metals in 2 separate concentrates.

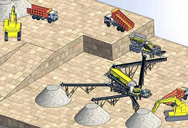

Ore flotation process plant

Ore flotation process plant process introduction: Ore beneficiation plant could be used for processing cooper ore, gold ore, iron ore, zinc lead etc. Each mineral has its special features. Gernerally, the whole ore dressing plant is devided into 3 steps.

Copper Ore Processing Plant - China Mining Equipment Supplier

Copper Ore Processing Plant. Hengcheng offers turnkey solutions for Copper flotation Plant. We are one of the leading project suppliers for Copper flotation Plant and we work closely with our customers to fulfill their specific needs for customized package solution. Specialized in the fabrication of these machines for 15 years and this enables us to be in a leading position in the field of Copper flotation Plant…

Flotation | ore dressing | Britannica

The flotation process was developed on a commercial scale early in the 20th century to remove very fine mineral particles that formerly had gone to waste in gravity concentration plants. Flotation has now become the most widely used process for extracting many minerals from their ores. Schematic diagram of a flotation separation cell.

ore flotation plant - fumorestaurant.com.au

Flotation is a method that is widely used in gold ore processing plant to process the rock gold,commonly used in dealing with highly floatable sulfide minerals...

Excellent Quality Energy Saving Copper Ore Processing ...

Copper ore flotation processing plant for saleflotation cell flotation china high efficiency flotation machine price for saleflotation machine flotation vibrating feeder iso ce quality isoce approved linear pulp vibrating screen find details about portable bf flotation machineplant plant crusherbf bf suppliers.

flotation under iron ore processing plant

Flotation of iron ore processing plant tailings of the iron ore slimes produced from the washing plants and tailing ponds of Kiriburu mines assaying up to 60% Fe, 3.34% SiO2, and 2.93% Al2O3. The Desulfurization of Magnetite Ore by Flotation with a

Sulphide Gold Ore Treatment by Leaching and Flotation Process

Problem with gold recovery from sulphide ore: How may a mill get the maximum recovery of gold from a sulphide ore, at the least capital cost and at the same time obtain the highest net return. This latter point is most important. In many cases a gold mill using an all-cyanide flowsheet with fine grinding of all the ore will report very low gold content in the tailings particularly on an ...

Mineral processing - Wikipedia

The water extracted from the ore by dewatering is recirculated for plant operations after being sent to a water treatment plant. The main processes that are used in dewatering include dewatering screens such as Sepro-Sizetec Screens , sedimentation, filtering, and thermal drying.

Gold Processing,Extraction,Smelting Plant Design ...

These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc., to achieve the processing plant of optimal and cost-efficient process designs.

Manganese Ore Processing Plant | Mining Equipment for Sale

Manganese Ore Processing Plant The process flow of the manganese ore processing plant is based on the results obtained from laboratory ore dressing tests and industry test. Magnetic separation process with 1 070 mm × 4 600 mm tank type ore washing machine has a good effect,. 1 Main equipment of manganese ore process plant

Summary of Fluorite Ore Flotation Process - JXSC Machine

Apr 24, 2019 · A great deal of research and production practice shows that flotation is a useful method for recovering fluorite ores, suit for large scale fluorite ore processing, the beneficiation method (flotation process and stone agent) varies from the ore characteristics. if you need a fluorite ore flotation machine, pls contact us.

Gold CIL process - Yantai Jinpeng Mining equipment, ore ...

Cyanidation ---carbon adsorption process is the most widely used in gold cyanide extraction process . The principle in brief is the carbon could adsorb liquid gold from cyanide solution . In 1970s , with the research and establishment of adsorption of carbon loaded with gold and the recovery of carbon discharge gold , make recycle the carbon and reduce the cost , and easy to process the gold ...

Mineral Processing EPC,Mineral Process Engineering, Ore ...

HaiWang is committed to solving the problems of mineral processing plant such as budget overspending, schedule delaying, disputes of the manufacturers, etcgold mining equipment. ... Iron ore beneficiation plant Mineral Processing Case. ... > Floatation is a main method to separate the ores by the different natures of wetting by wat.

Mining Flotation Cell For Ore Processing Plant - Mining ...

Flotation of iron ore processing plant tailings HTA were carried out with a Hallimond tube and Denver flotation cell The selective flotation of pyrite from arsenopyrite was …

Fate of red mud lakes at Burnside complex tied to future ...

Former acting plant manager Peter Odgers now says the process is nearly completed. His last day was Aug. 28, and only a skeleton crew remains to maintain the 2,500-acre complexs mine waste ponds ...