floating support for ball mill - dafni-bremerhaven.de

Mar 29 2019 · The wooden base will serve as the support for the ball mill. It can be made by resting the wooden platform on top of the two 1"x10"x4" (2.54cm x 25.4 cm x 10.16 cm) pieces of wood. Place one smaller piece on either end of the platform and screw them in place using four stone screws evenly spaced across. 3 Views 20K Read More

Floating Support For Ball Mill - afri-culture.be

Floating Support For Ball Mill Trunnion Bearing Assembly Ball Mill & Rod Mill On smaller mills rigid or swivel type bearings support the mill trunnions. The lower half of such bearings are lined with bronze or a special mill babbitt which is peened in place and bored to fit the trunnion.

floating support for ball mill - barta-immobilien.de

floating support for ball mill Trunnion Bearing Assembly Ball Mill & Rod Mill Ball Mill TRUNNION BEARINGS. Swivel type lead-bronze bushed trunnion bearings are generally furnished on large diameter ball Mills.

floating support for ball mill - kinderopvangmarmotje.be

Shell-supported ball mills are becoming the mills of choice over those with trunnion bearings. Depending on the size of the mill there are two four or six sliding shoes per bearing to 8 000 kW and with a dual drive up to 16 000 kW. Thanks to its floating shaft with hardened toothed wheels and its …

floating bearings on ball mills - Products - Kefid Machinery

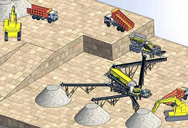

floating bearings on ball mills. 250tph river stone crushing line in Chile. 200tph granite crushing line in Cameroon. 250tph limestone crushing line in Kenya. 250tph granite crushing line in South Africa. Kefid 120tph granite crushing line in Zimbabwe. 400tph crushing plant in Guinea. Chat Online

Ball Mill Trunnion Bearing Lube System

On a 11’-6” x 22’-0” Ball Mill, the trunnion bearing lubrication system provides continuous low pressure flood oil for cooling and lubrication of the bearings, and high pressure oil for hydrostatic lift of the feed and discharge trunnions during start-up of the mill. System monitors including pressure switches and flow monitors are provided, along with temperature sensors that monitor ...

Trunnion Bearing Assembly Ball Mill & Rod Mill

Metallurgical ContentBall Mill TRUNNION BEARINGSTrunnion BRONZE BUSHINGSTRUNNION BASE AND CAPBall Mill LUBRICANT JACKSBall Mill PINION SHAFT BEARINGS The first part of the mill that we will look at is the TRUNNION BEARING. This is a HYDROSTATIC BEARING which is a slow moving bearing that carries a heavy load. Usually it is constructed from Babbitt’s metal. If you happen to …

How Ball Mills Work (Engineering and Mining) - YouTube

Jun 20, 2019 · Learn how a ball mill works, all of its main parts and some of its design features! This 3D animated video allows you to see all the internal parts of a ball...

Types of Ball Mills | Our Pastimes

All ball mills consist of rotating cylinders that contain hard (usually metallic) balls that do the grinding. There are three types of ball mills: horizontal, vertical and industrial. Horizontal Ball Mills. Horizontal ball mills are the most common type. The basic design is the same but the details can vary slightly.