Crusher - Wikipedia

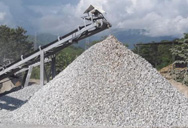

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust.. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of …

Primary Crusher - an overview | ScienceDirect Topics

The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator. Secondary coal crusher: Used when the coal coming from the supplier is large enough to be handled by a single crusher. The primary crusher converts the feed size to one that is acceptable to the secondary crusher.

Primary gyratory crushers - liming

Check out the liming Superior™ MKIII primary gyratory crusher 3D animation or brochure for a more detailed look inside this revolutionary primary gyrtatory crusher. Higher throughput. limings Superior™ MKIII primary gyratory crushers have new …

crusher for primary secondary crusher - …

Primary Crusher an overview ScienceDirect Topics. Figure 6.4 is a typical set-up where ores crushed in primary and secondary crushers are further reduced in size by a rough roll crusher in an open circuit followed by finer size reduction in a closed circuit by a roll crusher.

primary crusher, primary crusher Suppliers and ...

838 primary crusher products are offered for sale by suppliers on Alibaba.com, of which crusher accounts for 88%, grinding equipment accounts for 2%, and mining machinery parts accounts for 1%. A wide variety of primary crusher options are available to you, There are 838 suppliers who sells primary crusher on Alibaba.com, mainly located in Asia.

Crushers - an overview | ScienceDirect Topics

A gyratory crusher includes a solid cone set on a revolving shaft and placed within a hollow body, which has conical or vertical sloping sides. Material is crushed when the crushing surfaces approach each other and the crushed products fall through the discharging opening. Hammer crushers are used either as a one-step primary crusher or as a secondary crusher for products from a primary crusher.

Primary Crusher Selection & Design

23-12-2015 · How you select your primary crusher will be based on factors like moisture content, maximum rock lump size, material density SG, abrasion index, degradability and it being prone to dusting or not. The crusher capacities given by manufacturers are …

Primary Crushing - Mineral Processing & Metallurgy

The term “primary crusher,” by definition, might embrace any type and size of crushing machine. The term implies that at least two stages of crushing are involved, but in many cases the machine which performs the function of initial crusher is the only crusher in the plant. The factors influencing the selection of a crusher …

What is primary crusher and types of primary …

What is primary crusher and types of primary crushers. Primary crushing reduces this run-of-mine rock to a more manageable size. The different types of primary crushers are: jaw crushers, gyratory crushers, impact crushers, and autogenous crushers. - PR11735770

primary crusher - Spanish translation – Linguee

For treating the ore, there are one primary crusher, one secondary crusher and one tertiary crusher, two mill crushers, one mill and two flotation circuits. southerncoppercorp.com Para el tratamiento del mineral, cuenta con una chancadora primaria, una chancadora secundaria, y una chancadora terciaria, dos chancadoras de molino, un molino, y dos circuitos de flotación.

ebook primary crusher dan sc - justabreak.nl

Crushing Equipment. limings stone crusher is designed to achieve larger productivity and higher crushing ratio. From large primary crushers jaw crushers and impact crushers to cone crushers and VSI sand makers as secondary or tertiary stone crushers, liming can supply the right crushers as well as complete crushing lines to meet your requirements.

HAZEMAG -primary impactors | HPI

For aggregate production and recycling industry, the HPI impact crusher is used in the pre-crushing role without a grinding path. The single rotor primary impact crusher of the HPI series is used in the cement industry with grinding path, for the production of a raw material with an ideal stone size distribution for further grinding in vertical roller mills.

components of a secondary crusher - Ketel Service …

With a gyratory crusher, at any cross section there are in effect two sets of jaws opening and shutting like jaw crushers.In fact, the gyratory crusher can be regarded as an infinitely large number of jaw crushers each of infinitely small width, and, as consequence, the same terms gape, set, and throw, have identical meaning in the case of the gyratory crusher.

primary crusher - Vertaling Engels-Frans

Online vertaalwoordenboek. FR:primary crusher. Mijnwoordenboek.nl is een onafhankelijk privé-initiatief, gestart in 2004.

difference between primary and secondary crusher ...

14-08-2013 · These crushers can be used as primary or secondary crushers to break up and further refine larger rock material. … Difference Between a VSI and a Cone Crusher.

Jaw Crusher for Primary Crushing - Fote …

Jaw crusher wroking at the site of Philippines FTM - Jaw crusher for sale Powerful Manufacturer: Fote Heavy Machinery Co., Ltd. is a high-tech enterprise integrating R&D, production, sales and service. Sold Worldwide: Our jaw crushers are exported to …

x superior primary crusher hydroset system

Home>Crusher and Mill >36 x 55 superior primary crusher hydroset system 36 x 55 superior primary crusher hydroset system 30" x 55" portable primary jaw crusher . 36 x 55 superior primary crusher spares. 36 x 55 superior primary crusher hydroset system-[crusher and , , and spare wear parts for sale with competitive price, superior, Jaw Crusher ...

Working Principle Of Primary Crusher

Jaw crushers are used as primary crushers, or the first step in the process of reducing rock. Get Price And Support Online; working and principle of crusher - mehraseducation. jaw crusher working principle as a power crusher equipment generally used in stone crusher is very hard raw materials . Jaw crushers are used as primary crushers, .

primary crushers for coal

primary and secondary crusher coal crusher. Primary crusher.Primary coal crusher used for larger coal size the primary coal crushers may be of different types such as 1 coal jaw, 2 coal hammer, and 3 ring granulator secondary coal crusher used when the coal coming from the supplier is large enough to be handled by a single crusher the primary crusher converts the feed size to.

P&Q University Lesson 7- Crushing & Secondary …

02-09-2019 · For impact crushers, a fully hydraulic crusher gap setting with automatic zero-point calculation can speed daily set-up. Featured only on certain mobile impact crushers, a fully hydraulic adjustment capability of the crushing gap permits greater …