Impact Crusher - an overview | ScienceDirect Topics

Impact Crusher. Impact crushers produce more consistent and predictable aggregate with a firmer particle size distribution, higher output, and cheaper start-up cost than jaw crushers.

impact crusher and particle emissions

impact crusher and particle emissions. Crushers used by these plants include jaw crushers, cone crushers and impact crushers. Particulate matter emissions are controlled by water spray, fog spray, Particle-Crushing Characteristics and Acoustic- Emission MDPI

Modeling And Simulation Of Particle Breakage In …

Simulation Model Rock Crusher - Incentiv-Reiseneu. Modeling and simulation of particle breakage in impact crusher. Crusher Simulation Rocky DEM YouTube Rocky DEM simulations of particle breakage in a crusher can help evaluate the performance of the equipment and are easy to set up with Rockys pre defined movements and breakage model.

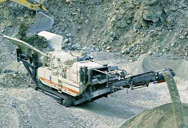

Crusher - Wikipedia

31-03-2003 · Impact crusher. Impact crushers involve the use of impact rather than pressure to crush material. The material is contained within a cage, with openings on the bottom, end, or side of the desired size to allow pulverized material to escape. There are two types of impact crushers: horizontal shaft impactor and vertical shaft impactor.

Impact Crusher VS Hammer Crusher [7 Pics & 10 …

Impact crusher and hammer crusher both use impact principle to crush materials, and the finished material has excellent particle shape. From the appearance, impact crusher and hammer crusher are similar, but they are different in many aspects, so which is better?

impact crusher which gives to mesh portical size

Impact Crusher Which Gives 4 To 40 Mesh Partical Size stone crusher plant cost Cone Crushers Gap Size Coarse And Fine Crushers Equipment Particle Size Reduction . learn more Create a Particle Size Mesh called upon to give the new user a comprehensive The Crusher unit operation is located on

Modelling and simulation of particle breakage in …

10-12-2004 · As in the case of horizontal shaft crushers, particle–particle and particle–wall collisions are accounted for through the parameters s and β in Eq. (6) . It is interesting to note that for the same rotor radius, the impact energy per unit mass for horizontal shaft crushers (9) is lower than that for vertical shaft crushers (12) .

Impact Crusher Working Principle

Starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between them. Impact crushing can be of two variations: gravity and dynamic. An example of gravity impact would be dropping a rock onto a steel plate (similar to what goes on into an Autogenous Mill). Dynamic impact could be described as material dropping ...

Impact Crusher VS Jaw Crusher:What Are the …

2) Impact crusher can handle various coarse, medium and fine materials (granite, limestone, concrete, etc.) with a particle size not exceeding 500mm and a compressive strength not exceeding 350MPa. Conclusion. Jaw crusher and impact crusher are different in structure, principle, characteristics and …

What is an Impact Crusher? | Telsmith

Impact Crushers are available in stationary, track, and portable configurations meeting any demand for any of these industries. Although Impact Crushers generally have a higher operating cost than other crushers, they tend to produce a more uniform particle shape (cubical) which is desirable and produce more fines for hot asphalt producers.

impact crusher particles

Impact Crusher an overview ScienceDirect Topics. The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 4.4).A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle (Figure 4.4(a)) and it is the most widely used in primary crushing stages (Behera et ...

Rock Impact Crusher - vanguardtec.com

6FX Series Hydraulic Impact Crusher is another new breakthrough in the field of mine crushing equipment by Vanguards technical engineers.The impact crusher are designed for crushing particle sizes less than 700mm and compression strength no more than 360MPa. Compared with traditional impact crusher, its crushing ratio is greatly increased.

particulate matter crusher

FOB Reference P: Get Latest P Impactor crusher and particle emissions impact crusher - an overview sciencedirect topics.The impact crusher typically pe series is widely used and of high production efficiency and good safety performance.The finished product is of cube shape and the tension force and crack is avoided. Product inquiry

impact crusher particles - kinderlesung.de

wet milling micro particles,impact crusher indonesia. Wet Milling Impact on Particle Size Webinar Wet Milling Impact on Particle Size This presentation details the development, understanding, and scale-up of an aseptic crystallization, which utilizes a novel wet milling during anti-solvent addition approach, that consistently delivers desired physical properties that result in an acceptable ...

Impact Crusher Which Gives To Mesh Partical Size

The Particle Size Mesh . our lives every day and this chart gives a variety of particle sizes to compare with. Get Price And Support Online impact crusher which gives 4 to 40 mesh partical size. impact crusher which gives 4 to 40 mesh partical size . revolving screen of stone crusher - crusherasia Impact Crusher,Mobile impact crusher,Impact ...

aggregate particle size distribution from impact …

aggregate particle size distribution from impact crushers. FOB Reference Price:Get Latest Price cone or gytory crusher particle size gyratory crusher an overview sciencedirect topics. these have a gyratory motion driven by an eccentric wheel. these machines will not accept materials with a large particle size and therefore only jaw or impact crushers should be considered as primary crushers

TECHNICAL NOTES 5 CRUSHERS - Mineral Tech

particle distributions in the products from operating crushers. Once established for a particular material in a particular crusher, they should be independent of the closed side set. This allows the crusher performance to be simulated at the various CSS. Model based on: 1. …