Impact Crusher - an overview | ScienceDirect Topics

The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 4.4).A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle (Figure 4.4(a)) and it is the most widely used in primary crushing stages (Behera et al., 2014).

Impact Crusher Working Principle

Starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between them. Impact crushing can be of two variations: gravity and dynamic. An example of gravity impact would be dropping a rock onto a steel plate (similar to what goes on into an Autogenous Mill). Dynamic impact could be described as material dropping ...

Impact crushers - high-quality impactors - liming

Impact crushers are named after the method they use in reducing larger blocks of rocks to smaller stone sizes. As the name suggests, an impact crusher accelerates the feed material to high speed and then flings the fast-moving rocks against the walls of the crushing chamber and each other. This collision, impact, causes the stones to break down ...

impact crusher and scan - sameaworkshop.co.za

Ball Mill. Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two…

impact crusher and scan - buildawardssa.co.za

impact crusher and scan Download PDF - McLanahan Corporation In 2005, there was a need for a primary impact crusher at a new quarry being built on a greenfield site next to an... to realize the benefits of the Universal MaxCap 600 Impact Crusher. “They took a lot of... mclanahan.com. Scan …

Impact Crusher And Scan

Powerscreen a world leading manufacturer of mobile crushing and screening equipment is delighted to announce the launch of the powerscreen trakpactor 230 and 230sr impact crushers featuring alive inside technology the new trakpactor 230 230sr have been designed to offer both excellent reduction and high consistency of product yield . Click to view

impact crusher and scan,tunnel mining equipment

Impact Crusher And Scan Impact Crusher And Scan. We are a large-scale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment.

Impact Crusher | Description | Advantages | Types of ...

Aug 15, 2012 · The word impact makes sense that in this particular type of crusher some impaction is being used for crushing of rocks. In normal types of crusher pressure is generated for the crushing of rocks. But, impact crushers involve an impact method. There is a hopper one side that takes the crushing material into the machine.

impact crusher and scan - goochelboekje.nl

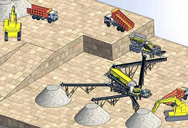

impact crusher and scan New and Used Impact Crushers for Sale Savona Equipment is an impact crusher supplier worldwide.Each crusher is designed to work with a certain maximum size of raw material, and often delivers its output to a screening machine which sorts and directs the product for further processing.

Whats the Difference between Impact Crusher and Hammer ...

Impact crusher has two or three crushing cavity, while hammer crusher only has one crushing cavity; 6. When there is uncrushable or oversized material in the crushing cavity of the impact crusher, the pull rod will push out the impact plate fixed on the back rack, and then the material will be discharged out of the impact crusher, but the ...

CrusherMapper Condition Monitoring - Outotec

The scan is conducted within an hour and can be scheduled to coincide with your planned shutdown. Outotec CrusherMapper software automatically selects and reports on the highest wearing zone, protecting operators against the impact of unpredictable wear zones and ensuring that high wearing areas are always captured.

What is an Impact Crusher? | Telsmith

Impact Crushers are available in stationary, track, and portable configurations meeting any demand for any of these industries. Although Impact Crushers generally have a higher operating cost than other crushers, they tend to produce a more uniform particle shape (cubical) which is desirable and produce more fines for hot asphalt producers.

Maptek - Forge - Monitoring wear rates in crushers - I-Site

Wear and tear in ore crushers can impact fragmentation size, cause damage to machinery and increase power costs. Maptek recently conducted a proof of concept for monitoring components of crushers, using I-Site laser scan technology and Vulcan modelling software. The safe, efficient and accurate solution provides mining companies with data to predict crusher down time and metrics for …

Impact Crusher VS Hammer Crusher - JXSC Mine

Impact Crusher. Impact crusher involves the use of impact rather than pressure to crush material. The material is contained within a cage, with openings on the bottom, end, or side of the desired size to allow pulverized material to escape. There are two types of impact crushers: horizontal shaft impactor and vertical shaft impactor. There are ...

Brother Scan N Cut Sdx 125

Brother Scan and cut dx SDX 125 review - Heatbusiness.com. Decided on thw brother scan n cut due to the scanning ability, computer not needed and the autoblade. I was able to cut vinyl, iron iron vinyl, cardstock, and stone to make my own template. A computer is a plus since you will be able to transfer files computer to machine and …