Vibrating Conveyors - Kinergy

Design Features of the Kinergy Driven Vibrating Conveyor. Kinergy has the most advanced vibratory machine technology available. Our designs include the following: Durability: Kinergy Vibrating Conveyors are built to last with an average of 20 or more years of productive use.

All About Vibrating Conveyors - Types, Design, and …

Figure 2 gives a common iteration of vibrating conveyor designs, where a drive system imparts an oscillatory force onto the trough with a specific frequency and amplitude. The trough stroke, or one full movement of the trough, is usually twice the amplitude of the vibration and the goal for most vibrating conveyors is to minimize this amplitude but maximize frequency.

Vibrating conveyors | Bruks Siwertell

Our modular vibrating conveyors offer an extremely efficient, multi-functional method of conveying and processing different sized bulk materials, including larger and longer pieces of processed wood. Their design ensures consistently high conveying speeds even under high loads.

Vibratory Conveyors

For more than 50 years Renold AJAX Vibrating conveyors have been used in a variety of industry applications for transferring many types of granular and bulk materials. Renold Ajax conveyor systems can also be modified to perform other functions such as screening, scalping, drying, cooling, grading and dewatering. Renold custom designs

Vibrating Conveyor - appliedvibration.co.uk

A vibrating conveyor is ideally suited to applications with high throughput rates - such as a bulk product transfer - where the conveying velocity is generally fixed.. A vibratory conveyor can take the form of open trough, enclosed trough or tube design; Conveyors are driven by singular or twin vibrator motor drives

Vibrating conveyors - Schenck Process

However, vibrating conveyors are relatively impervious to congestion or conveyor channel blockages. They generally work freely again without intervention. It should be noted when planning the design that they work most efficiently in a horizontal or inclined direction.

Vibrating Conveyors - Webster Industries

• Limited length of conveyor per drive. DESIGN FEATURES • CONTROLLED VIBRATION The movement of material on the pan of a vibrating conveyor is dependent on the vibratory motion of the pan. On all Webster vibrating conveyors, amplitude, direction and frequency of the vibratory motion are selected and controlled. This provides a gentle hopping

Vibratory Conveyors

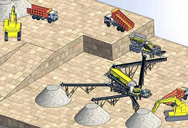

Table of ContentsClassification of Conveyor TypesMaterial Movement along Conveyor TroughTrough Amplitudes and Forces for Different Drive Mechanisms Vibratory or oscillating conveyors can be found in all types of industry, handling virtually any granular bulk material. They can be combined with other process functions, such as screening, cooling, drying and de-watering, while conveying. The ...

(PDF) SOME SPECIFICS OF VIBRATORY CONVEYOR …

22-08-2020 · Several possible vibrating conveyor designs—the “sealskin” conveyor, the “jerk” conveyor, the conveyor with inclined motion and the conveyor with out-of-phase motion—are first ...

Vibrating Conveyor - large pan & trough design - …

https://www.tinsleycompany.com - This type of Vibrating Conveyor has a large pan and trough and is used to convey heavy, abrasive and very hot materials for ...

theory on design of vibrating conveyors

Theory Design Conveyor - mmesaorgvibrating conveyor theory theory on design of vibrating conveyors Basic Theory The Basic Theory of Conveyors, The flightfree vibrating conveyor, .vibrating conveyor theory - yogamayacomfortsintheory on design of vibrating conveyors theory of vibrating feeder - SAM Crushers,Jaw Crusher,- theory on design of vibrating conveyors,Conveying/Feeding | .vibrating ...

vibrating conveyor design - fietswereld …

Vibrating Conveyor Vibration by Design. A vibrating conveyor is ideally suited to appliions with high throughput rates such as a bulk product transfer where the conveying velocity is generally fixed.. A vibratory conveyor can take the form of open trough, enclosed trough or tube design …

Alvibra: Vibrating Conveyor | Vibratory Feeder | …

vibrating sifters, vibration conveyor, vibratory feeder Welcome to Alvibra A/S – your specialist in vibration technology Alvibra is an innovative and customer-oriented company, which offers a wide range of conveyors, feeders & sifters based on vibration technology to handle powder and granules as well as other products such as foodstuffs.

Vibrating Feeders and Conveyors / Locker Wright …

Feeding and Conveying, Locker Vibrating Feeders & Vibrating Equipment. Locker are a long established and highly regarded leader in the design and supply of vibrating feeders, conveyors, vibrating equipment and ancillieries. Renowned for performance, longevity and quality, the Locker brand was acquired by the Wright Group of Companies in 2015.

Vibratory Conveyors - Alvibra: Vibrating Conveyor

Alvibra Tube Conveyor - Powered by VibraDrive. The Alvibra Tube Conveyor (ATC) is a unique, robust and effective vibratory conveyor using a closed tube design, well suited when the requirement is a closed and dust proof transport system and a sanitary design that is easy to clean.

Vibrating Conveyor Design - bulk-online.com

10-01-2015 · Hi all, I want design vibrating conveyor with capacity of 35 TPH. width and length of the pan 2x12 M for sugar plants. Can any body suggest me the inclination and eccentricity can be consider. and also suggest me the power calculation for that.