How copper ore is concentrated by froth flotation process ...

Copper Mining and Extraction: Sulfide Ores. From the formula, it is clear that iron and sulfur have to be removed in order to produce copper The roasting process: changes some of the CuFeS 2 to copper oxide; removes some of the sulfur as sulfur dioxide; This is done by heating the concentrated ore from froth flotation It is heated to between 500 C and 700 C in air

How Copper Ore Is Concentrated By Froth Flotation Process

Copper is extracted from its principal ore copper pyrites cufes 2.The ore is concentrated by froth flotation process.The concentrated ore is roasted in a reverberatory furnace when the.Copper pyrite is concentrated by.Extraction of copper from copper pyrite lets learn nepal. Why Is The Froth Flotation Method Only Used For

Froth Flotation Of Copper

The slurry is a mix of valuable copper ore minerals and worthless rock, called gangue pronounced gang. The slurry is placed in a tank and a process called froth floatation is used to separate the copper minerals from the gangue. stone reagents called collectors are added to the slurry and bind to the copper particles, making them

How Copper Ore Is Concentrated By Froth Flotation Process

A Froth Flotation Process Is Used To Concentrate C . A froth flotation process is used to concentrate copper ore. It is a two stage process with a rougher stage followed by a cleaner stage. The cleaner tailings are returned to the rougher flotation. How Copper Ore Is Concentrated By Froth Flotation Process

Froth Flotation Process Machine For Copper

Froth flotation process for copper . Froth flotation method jxsc machine. 20191216the froth flotation method is widely used to treat various veins of gold and silver ores for the following reasons 1 in most cases the froth flotation process can enrich gold and silver in sulfide concentrate to the greatest extent and discard a large number of tailings thus reducing the smelting cost.

Copper Mining and Processing: Processing of Copper Ores ...

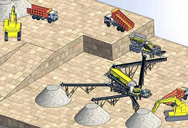

After the copper ore is crushed, liquid is added to make it a slurry. The slurry is a mix of valuable copper ore minerals and “worthless” rock, called gangue (pronounced “gang”). The slurry is placed in a tank and a process called froth floatation is used to separate the copper minerals from the gangue. stone reagents called “collectors” are added to the slurry and bind to the copper …

froth flotation process for gold copper

Dec 20, 2018· The froth flotation method is widely used to treat various veins of gold and silver ores for the following reasons: (1) In most cases, the froth flotation process can enrich gold and silver in sulfide concentrate to the greatest extent and discard a large number of …

(PDF) A Review of the Flotation of Copper Minerals

Oxidic ore can be concentrated using flotation or, if it has a low acid demand, it may be economic to acid heap leach the stockpile. The recovery of these copper minerals by flotation or...

crushed zinc ore production process-froth flotation of ...

Flotation Cell; XCF Air Inflation Flotation Cell; Jjf Flotation And Wemco Flotation; Magnetic Drum; Spiral Chute; Bf Flotation Cell; ... crushed zinc ore production process; crushed zinc ore production process. Efficient Thickener. Efficient Thickener. Hydraulic Motor Driving Center Thickener.

Copper ore flotation process - YouTube

The flotation machine is used for the separation of the nonferrous black metal as well as the separation of the non-metallic materials such as the coal fluor...

Copper Ore - an overview | ScienceDirect Topics

Beneficiation of copper ores is done almost exclusively by selective froth flotation. Flotation entails first attaching fine copper mineral particles to bubbles rising through an ore–water pulp and, second, collecting the copper minerals at the top of the pulp as a briefly stable mineral–water–air froth.

bauxite flotation concentrate

bauxite flotation concentrate_Separation of silica from bauxite via froth flotation ...Hence, after flotation, a magnetic separation operation was introduced to improve once again the available alumina grade in the concentr

Froth floatation process is used to concentrate magnetic ores.

Dec 20, 2019 · Answer Froth floatation process is used to concentrate sulphide ores. In some cases, sulphide ores of copper, zinc and lead concentration are brought by this method. It is the referential wetting of the ore by an oil.