Cement mill - Wikipedia

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement.Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL …

• Vertical roller mill (VRM) • Ring roller mill or Horo mill Even though there are various types of systems available for cement grinding, ball mills are predominantly used machines for cement grinding in large number of cement plants. In this stone authors are covering the process diagnostic study of Ball mill for cement grinding. 2.

Vertical Christmas Tree, Pink Cement Background …

Photo about Close Up Of Green Christmas Tree With Pink Cement Background. Vertical Christmas Greeting Card. Image of background, concrete, winter - 100967929

Vertical Concrete Mix for Resurfacing Walls - The …

11-08-2020 · Most vertical mixes are composed of a blend of cement, graded lightweight aggregates, polymers and admixtures. Some are also fiber-reinforced. They are mixed with a paddle or mortar mixer and then applied with a hand trowel, similar to plaster, or even with a shotcrete gun, depending on the size of the area to be resurfaced.

Products | CTS Cement

Cement All® is a high-performance, fast-setting concrete repair material that is durable in wet environments. Apply Cement All from featheredge to 4” thick. Use for general and structural concrete repair, doweling and anchoring, industrial grouting, formed work, vertical …

How to Repair Cracks in Vertical Concrete Surfaces …

Make cosmetic and waterproof repairs to concrete, masonry and stucco walls. Sealing the cracks with QUIKRETE is an easy project for any skill level. This vid...

Of Cement Vertical Mill Over Ball Mills

Cement grinding Vertical roller mills versus ball mills. grinding of raw materials. The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill system.

Particle Shape Difference For Cement Vertical Mill

Vertical Cement Mill authorSTREAM. slide 3 System power kWht 41 33 28 Annual electricity savings 10000 yuan 400 700 Metal wear gt 50 Steel ball 30 Steel ballroller surface 5 Grinding rollergrinding table Drying capacity Weak Medium Strong As can be seen from the table the vertical roller mill system is superior to the ball mill and roller press system in the aspect of power saving.

pet coke cost in vertical coal mill in cement process

vertical mill for coke grinding. vertical mill for coke grinding How to grind stone coke in vertical roller mill designed for. Dec 05, 2015 How to grind stone coke in vertical roller mill designed for normal coal. dear experts, we are having loshe mill LM26-3 for coal grinding, now we want to grind stone coke from this mill with a residue of 2% at 90 mic mesh. what changes we have to do or is it ...

Maintenance Routines For Vertical Roller Mill For …

Model: 1300M vertical roller mill Buying Time: 2016.12 Return Content: Thanks for the Cliriks vertical roller mill, the output of my powder making factory has improved efficiency by 20%. And compare with other vertical mill I had used. 1300M vertical roller mill, …

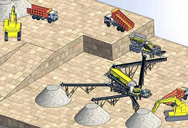

cement vertical compound crusher figure

Cement Vertical Compound Crusher Figure cz-eu. cement vertical compound crusher figure. cement vertical compound crusher figure. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any size-reduction requirements including quarry, aggregate, and different kinds of minerals.